Holistic Industrial Design: Our Process from Idea to Production

Looking for an industrial design agency? Eckstein Design guides your product from idea to production in 7 clear steps. Specialized in capital goods, B2B, and medical technology. Learn more now!

Holistic Industrial Design

Our Process from Idea to ProductionUnser Prozess von der Idee zur Serie

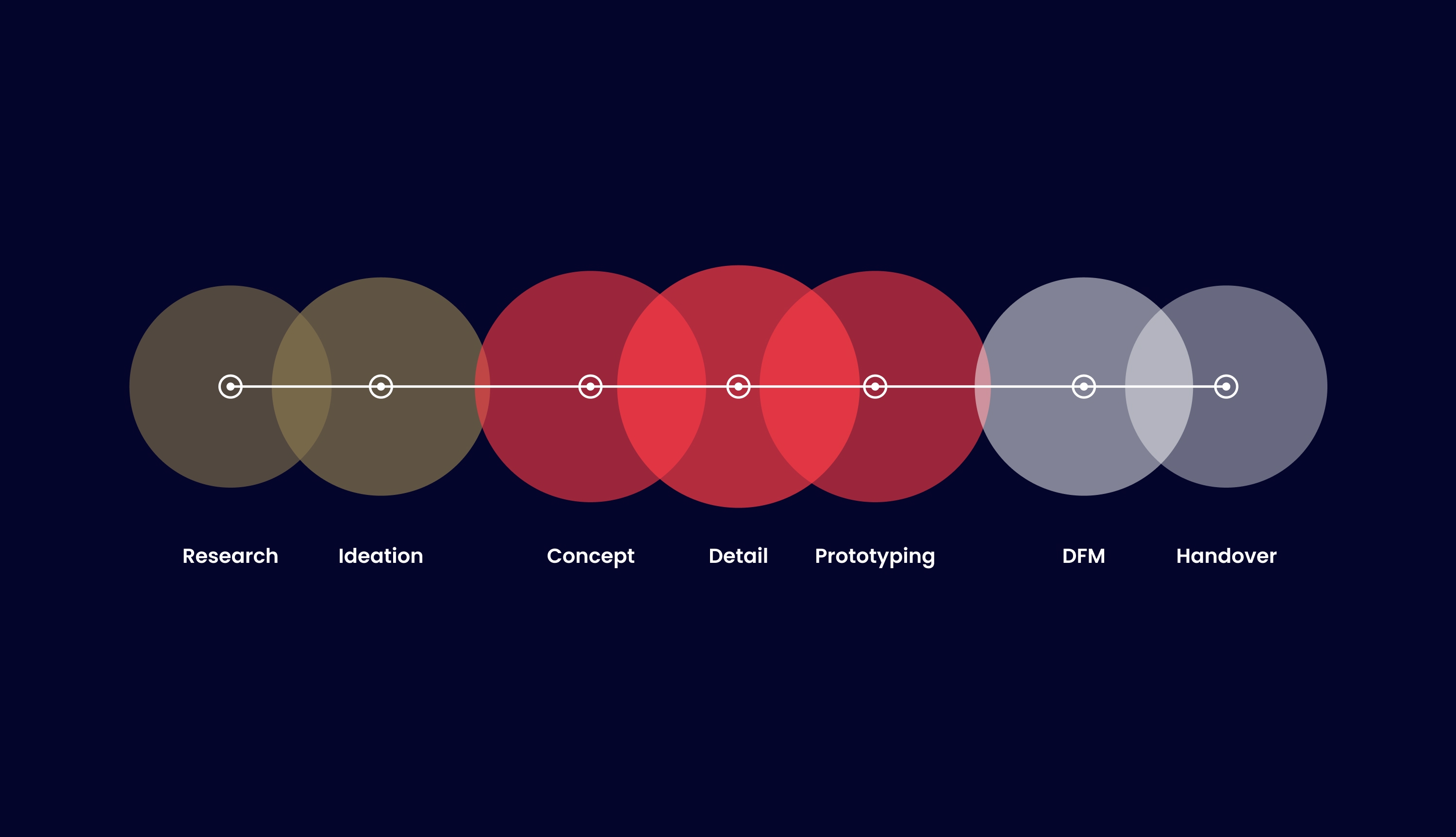

At Eckstein Design, our design process systematically leads from the initial idea to series production. We work through seven key phases: Research & Analysis, Ideation, Concept Development, Detail Design & CAD, Prototyping & Testing, Design for Manufacturing (DFM), and Handover to Production. Each phase has clearly defined goals, deliverables, and decision points — from user analysis to production-ready implementation. Our approach integrates design, engineering, and user focus into a transparent process that reliably leads to market-ready products.

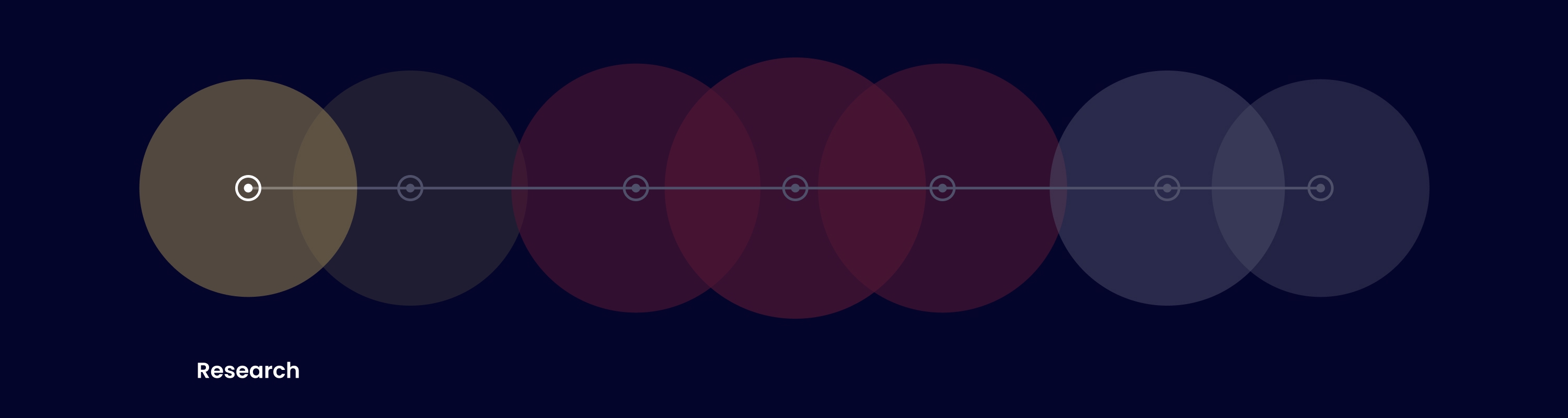

1. Research & Analysis – The Foundation of Informed Product Design

Every successful project starts with a sound analysis. During a kick-off workshop, we define objectives, requirements, and the project framework together with our client. The subsequent research phase includes:

- Market analysis & benchmarking: Identifying trends and opportunities for differentiation.

- User research: Interviews, observations, and personas help us uncover genuine user needs.

- Requirements & specification sheet: All insights are translated into a clear set of requirements as a basis for concept development.

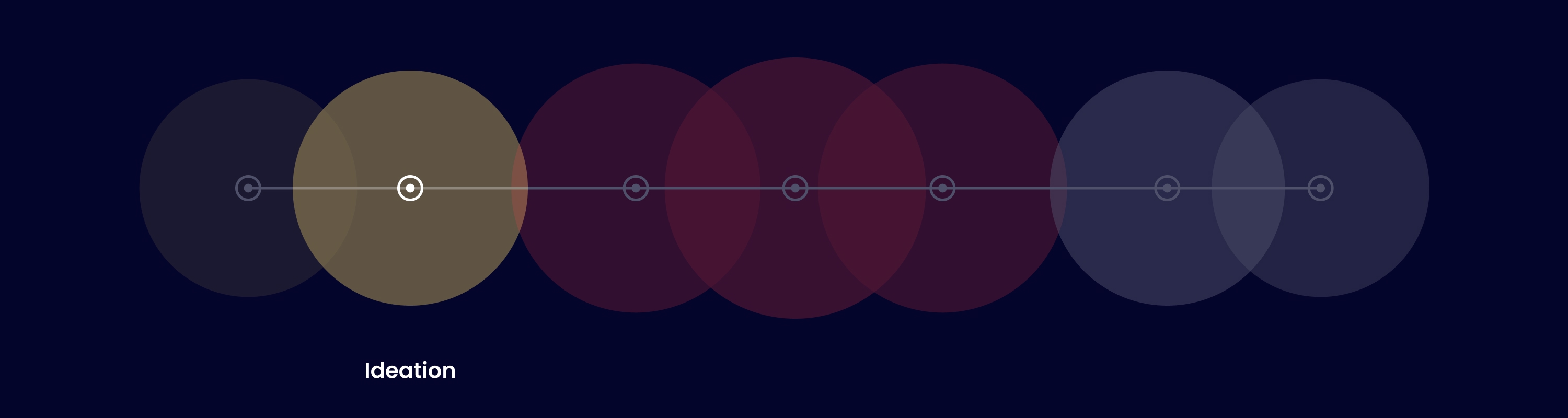

2. Ideation – Unleashing Creative Solutions

In the ideation phase, we develop the creative DNA of your product. Using methods like Design Thinking and interdisciplinary workshops, we explore a wide range of possibilities:

- Creative workshops with cross-functional teams

- Sketches and scribbles to quickly visualize innovative ideas

- Evaluation based on usefulness, feasibility, and brand fit

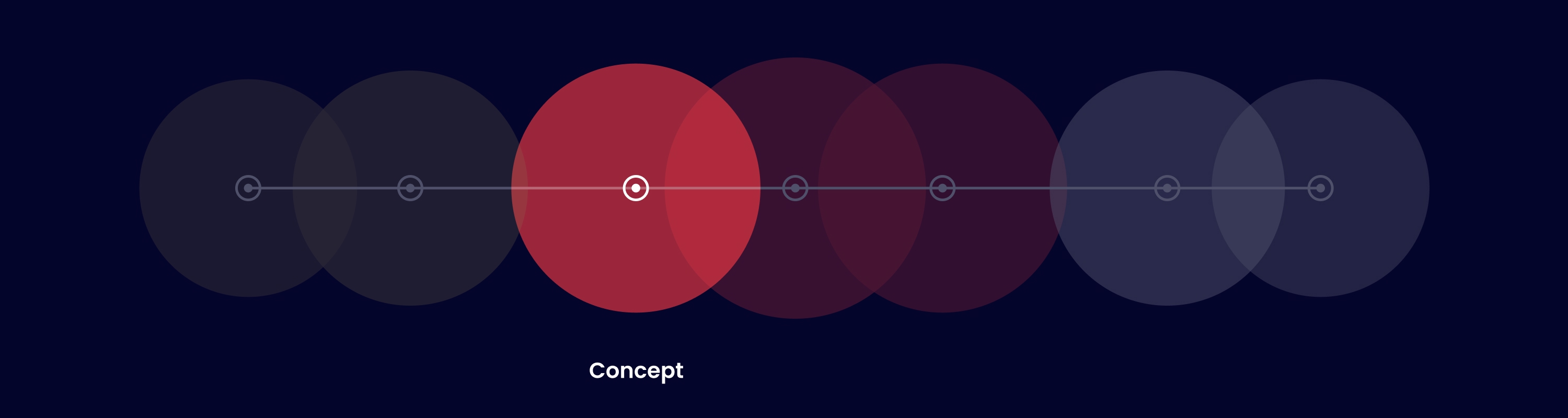

3. Concept Development – From Idea to Tangible Product Vision

The best ideas are developed into concrete product concepts. We typically create 2–3 concept variants to explore different directions. These are visualized as sketches, renderings, or initial CAD models.

- Ergonomic and interaction concepts tailored to the target audience

- Evaluation against user and brand requirements

- Selection or combination of the best concept

4. Detail Design & CAD – Refinement and Feasibility

Aus dem gewählten Konzept entsteht nun das realisierbare Produktdesign . Hier fließt unsere Engineering-Kompetenz voll ein – Designer und Ingenieure arbeiten eng zusammen, um Form, Funktion und Fertigung optimal zu verbinden.

Key elements of this phase:

- 3D CAD design: Detailed construction of all components, including materials and tolerances

- Technical feasibility: Early validation of robustness, ease of assembly, and manufacturability

- Draft angles & manufacturing-oriented design: We already integrate DFM aspects like part separation, wall thickness, and demolding at this stage

- Rapid prototyping: Early prototypes to validate ergonomics and function

- Iterative reviews: Continuous alignment with the client until the design freeze

5. Prototyping & Testing – Validation and Optimization

By building physical models, the design becomes tangible. We create prototypes at different fidelity levels to test functionality, usability, and ergonomics.

Process steps:

- Development of functional and appearance prototypes

- Usability testing with real users (e.g., in accordance with IEC 62366 for regulated industries)

- Iterative design improvements based on test feedback

6. Design for Manufacturing – Ensuring Production Readiness

Before production begins, we ensure cost-efficient manufacturability. Design for Manufacturing ensures your product can be produced economically and with high quality. Components are optimized for manufacturing and assembly.

Key focus areas:

- Evaluation of materials and manufacturing processes (e.g., injection molding, CNC, die casting)

- Design adjustments for easier production and assembly (DFA)

- Definition of tolerances and quality controls

- Close collaboration with manufacturing partners

7. Handover – Smooth Transition to Production

We support the transition into manufacturing. All relevant CAD data, bills of materials, drawings, and assembly instructions are provided. Together with production partners, we review tooling, first-off samples, and production processes.

- Data handover: Delivery of complete CAD files, drawings, and BOMs

- Production support: Coordination with manufacturing partners and review of initial parts

Specialization: Industrial Design for Medical Devices

In regulierten Märkten wie der Medizintechnik gelten besondere Regeln (MDR, ISO 13485).

Eckstein Design integriert regulatorische Anforderungen wie Risikoanalysen und Dokumentation direkt in den Designprozess.

Wir verbinden Ästhetik mit Normkonformität für sichere und innovative Medizinprodukte.

Conclusion: Design That Goes into Production

A clearly structured process makes great design reproducible. From analysis to creative concepts to production readiness, we guide you step-by-step from idea to market success. As your industrial design agency, we bring together creativity, engineering, and industry knowledge to develop holistic solutions — for products that function technically, delight users, and succeed in the market.

Let’s realize your next product innovation together. Contact us for an initial consultation – no obligation.